Bending Machine Standard Line

Bending Machine Standard Line Demo video

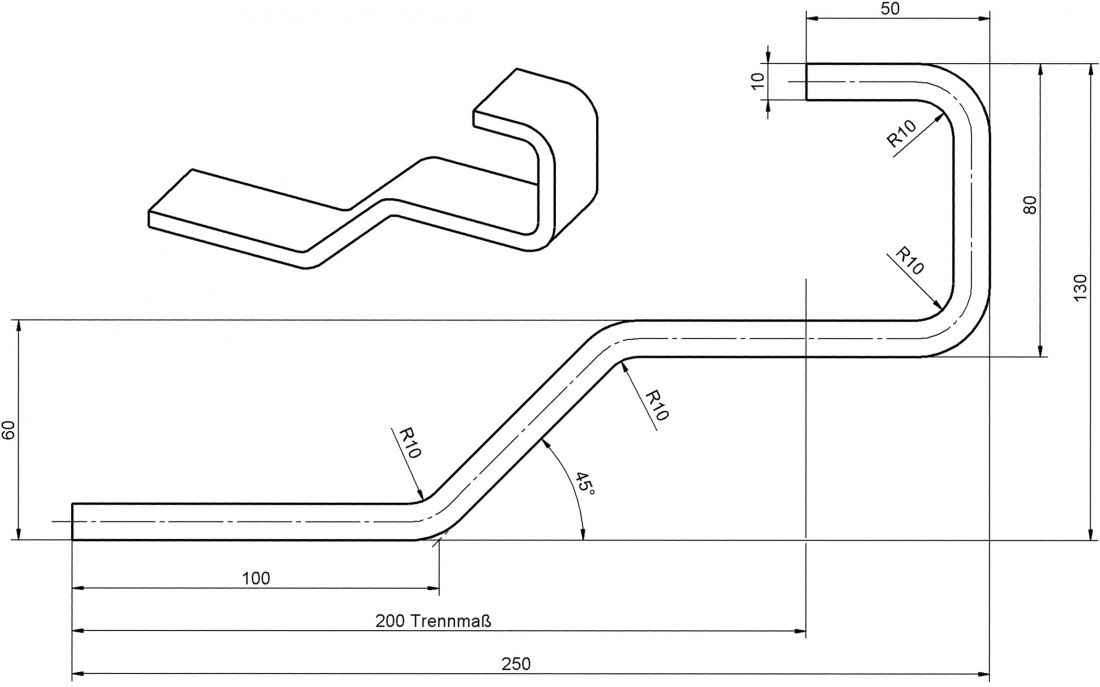

Special Bending tools

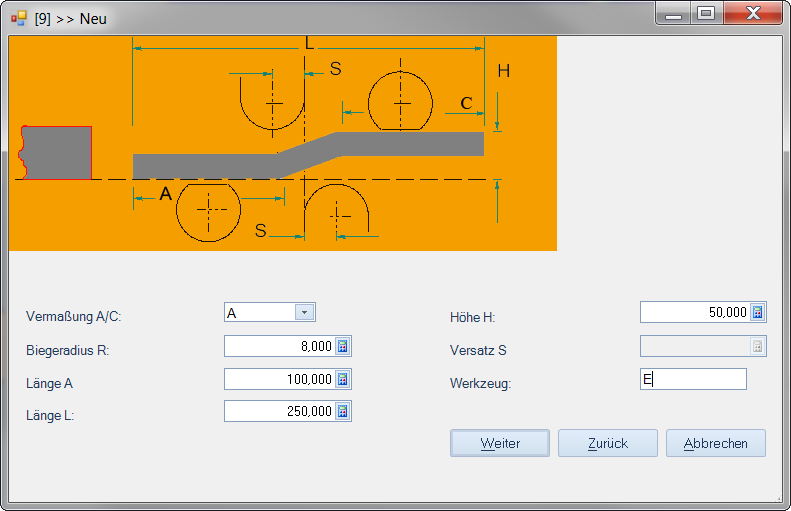

Offset Bending, Edge Bending, Twist Bending

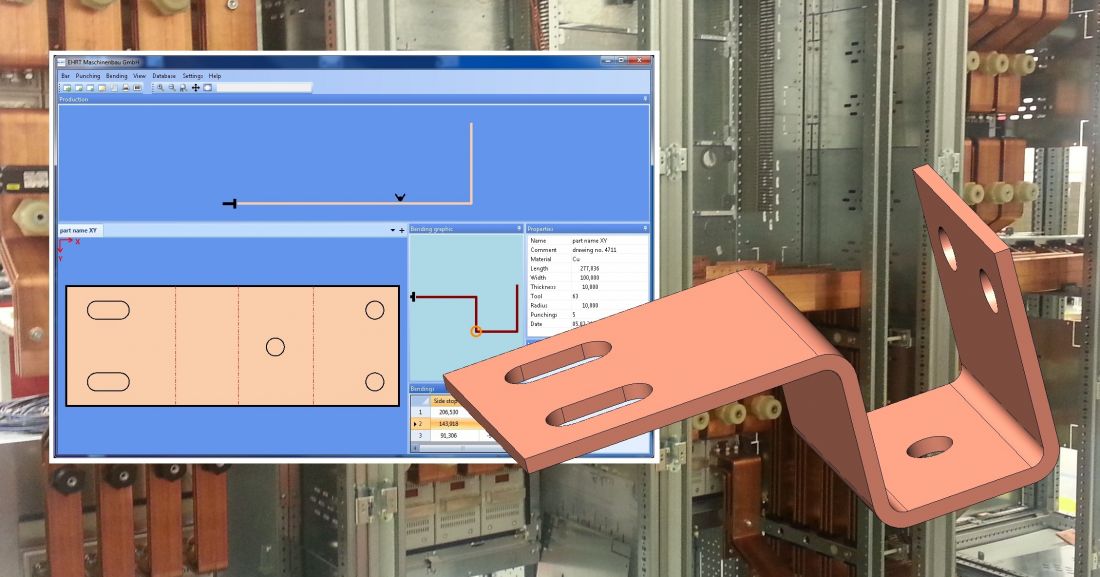

EHRT bending machines are exceedingly powerful CNC bending machines which allow bending of single pieces and small batches just as accurately and efficiently as series-produced parts. Due to a calculated spring back compensation and the use of electronic tools, a bending accuracy of +/- 0.2° is achieved beginning with the very first piece. A plug-in system enables a quick and easy change of tools.

MODULAR CONSTRUCTION

The reason behind the design of our Standard Line was to bring high flexibility to our customers. The basic machine supports mobile use and can even be transported to a construction site with little effort. It is suitable for serial production with an CNC stop, a work bench, and Windows® Software. Its modular construction offers an affordable entry into the EHRT bending technology.

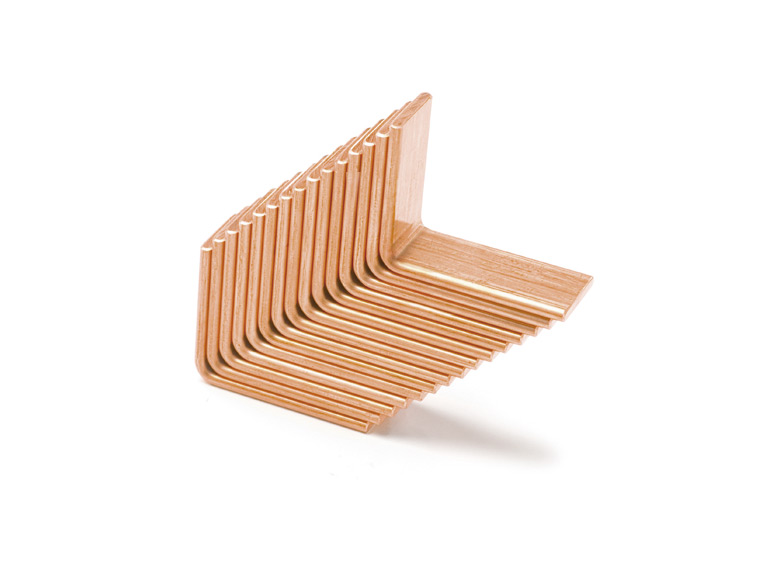

WORK PIECES

Materials of up to 200 mm in width and 30 mm in thickness can be bend.

CNC STOP

The EHRT bending features a CNC stop with a traverse path of approximately 2000 mm. The bending software PowerBend accurately calculates the flat length as well as the stop position and transfers the results directly to the CNC control unit. High production accuracy is assured.

ANGULAR MEASUREMENT

Our measuring accuracy is 0.1º. This is attained by using bending prisms with electronic angular measurement technology. The computer then calculates the required final stroke. The spring back of every bend is compensated regardless of material type. Our high angle accuracy of +/- 0.2º is achieved instantly with the first work piece. No adjustments are required. Material waste amounts will drop considerably. Even inconsistencies within a single piece of material are automatically adjusted.

STROKE MEASUREMENT

If the bending prisms with integrated angular measurement cannot be used due to their size, bending prisms without angular measurements can be used. Perhaps the distance between two bends is too short. In such cases the control unit can be switched from angular to stroke measurement. This method allows the selection of the bending ram distance. Setting accuracy is +/- 0.1 mm. A final stroke is usually not required.

ON-GOING DEVELOPMENT

This line was developed by incorporating many customer requests plus more than 50 years of experience in the bending machine industry. This machine is our most ergonomic machine to date.

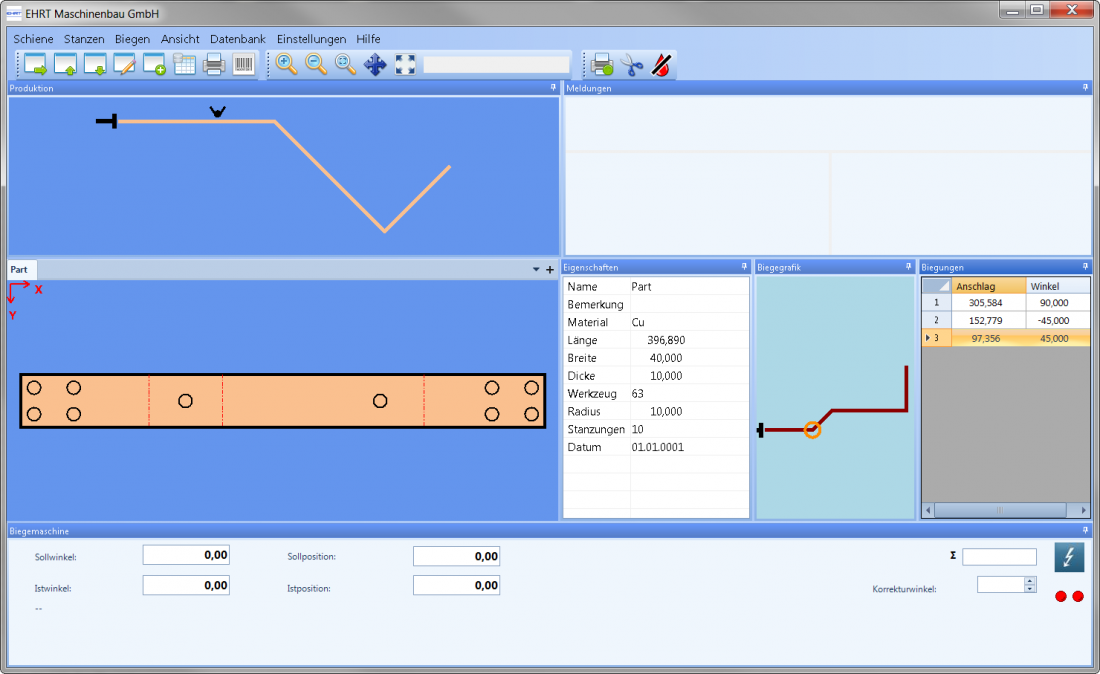

BENDING SOFTWARE POWERBEND

EASY HANDLING

The Microsoft Windows® based software, PowerBend, is easy to learn. No CNC programming skills are required. All necessary inputs are prompted and displayed on the screen. Inputs can be corrected at any time and minimum distances are checked instantly to guard against improper inputs. The operator is allowed to use outside, inside, center line, and radius dimensions. Software can be switched between mm and inches.

CALCULATED VALUES

The PowerBend software automatically calculates the flat length of each part being bent and determines the exact position of the side stop. Up to three bends can be calculated for one work piece.

PROGRAM STORAGE

The program for each work piece can be stored as alphanumeric names up to 24 digits. The database allows storage of more than 200.000 different parts which can be located easily using the search and sort options.